With Spilling on the team: Municipal and regional power supply companies.

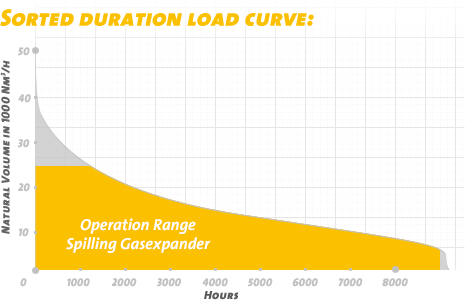

Gas transfer stations that are installed in the utlities to distribute natural gas to the consumer networks of towns and communities must be able to compensate the considerable fluctuations of the gas supply depending to the time of the year and day.

That is why the optimum size of the Spilling unit is always selected under consideration of the load fluctuations of the gas network and the controllability of the expander unit.

Each expansion machine has an operating range that has an upper and a lower limit, which should match the respective load profile optimally. Only this way can a largely continuous operation of the plant so with a high electricity production (kWh) and the respective economic efficiency be ensured. In detail:

- If the gas expander is over-dimensioned, it has a high output during peak load times, however the capacity cannot be fully utilised during basic load times and might have to even be switched off.

- If the gas expander is under-dimensioned, it can be operated continuously, however probably energy recovery potential remains unused and the specific investment costs will probably be too high.

This is the reason why more and more utilities opt for Spilling natural gas expansion machines:

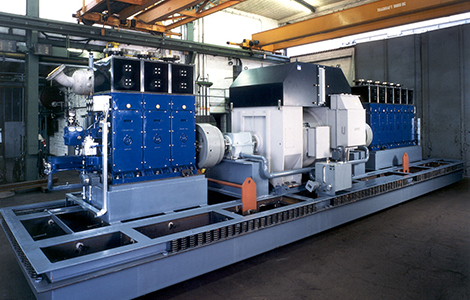

The modular design and the outstanding partial load efficiency factor of this piston expander make it especially suited for use in the gas transfer stations of electricity generation plants.