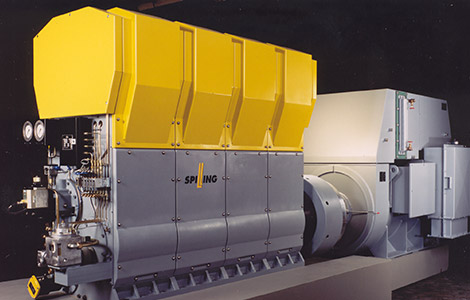

The Spilling gas expander: first choice for 40 years.

Gas expansion plants utilise the pressure gradient between natural gas transport networks and the distribution systems or consumers to extract mechanic and electric power.

The Spilling gas expander has been the first choice for a number of utility and industrial companies already since the end of the 1970s. Today companies utilise it than ever before for their plants in Germany and abroad – its huge operating range, at constant efficiency, makes the engine perfectly suitable for applications in pressure reducing stations with highly varying gas flows.

Today gas expansion plants are the power plant type which exhibits the highest level of conversion efficiency for the electricity. Depending on plant design, 80 - 90% of the additional fuel energy required for the Spilling expansions engine ist converted to electricity. This means that fuel efficiency is far superior to that of the most modern gas and steam power plants.

The Spiling gas expanders are extremly resource-saving in operation and contribute to the overall reduction of CO2 emissions. If waste heat for the preheating is used, the power generation can bring CO2 emissions nearly to zero. The volumetric control guarantees a high power yield due to consistently high efficiency levels over a wide operation range.

That makes the Spilling gas expander an interesting solution to increase operational energy efficiency:

- for municipal gas supply companies and

- industrial companies with an in-house gas transfer station.

Technical Data

| Output | from approx. 150 to 3,000 kW |

| Rated speed | 750, 900, 1,000 min–1 variable rated speeds are possible |

| Inlet pressure | from 6 to approx. 60 bar |

| Discharge pressures | from 50 mbar to 25 bar |

| Gas volume flows | from 5,000 to 100,000 Nm³/h |