Industrial companies with high gas purchases have a partner: Spilling.

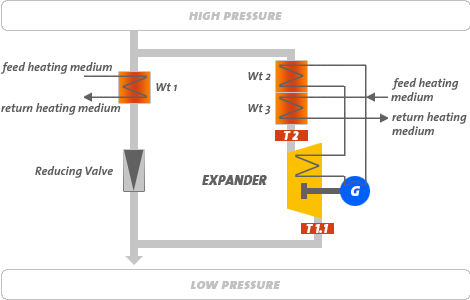

For many companies energy-intensive production processes or operating gas engine power plants to generate domestic electricity mean that they require their own gas transfer stations that meet the natural gas demands continuously. Here fluctuating load profiles that are to be reckoned with depending on the type of supply processes and the size of the plant.

In the processes of many companies of the most diverse industrial sectors

- excess heat as exhaust heat e.g. from

- the steel production

- the glass production

- chemical processes

- gas turbines or gas engine power plants

- excess heat as

- steam or hot water

occur, which they must discharge unused into the environment in the worst case.

The optimal prerequisites for operating a gas expansion plant are given when high gas flowrates occur together with excess heat. This means that domestic electricity can be generated besides gaining the heat needed to pre-heat the gas from the operational excess heat using an expansion motor. A properly designed expander plant converts nearly 100% of the heat input into electrical work – meaning that this electricity is generated without producing additional CO2 emissions.

The application range of Spilling gas expansion plants covers

| Gas volume flows | from 5,000 to 100,000 Nm³/h |

| Outputs | approx. 100 to 3,000 kW |

| Inlet pressures | from 6 to approx. 60 barg |

| Outlet pressures | from 50 mbar to 25 barg |