Industrial product drying with overpressure dryer

A large part of the heat quantity used in drying processes is required to evaporate the water contained in the moist product. If drying takes place under atmospheric conditions and the escaping moisture is even mixed with air (e.g. during drying in a hot air stream), it is difficult to recover the heat of evaporation of the escaping moisture or to make it usable again in another way. However, with some clever optimizations and exploitation of possible efficiency measures, there are promising approaches that help to save energy costs and protect the environment.

If product drying takes place in a (steam-heated) overpressure dryer, the moisture escapes at the given overpressure. Mixing with air does not take place here. This makes it possible to make the evaporation heat contained in the escaping moisture usable again by means of mechanical vapor compression. The higher the pressure level of the drying process, the easier and more energy-efficient the subsequent vapor compression can take place.

Example of steam recycling in pulp drying

Our following project example, which we realized in Sweden, shows how a new, energy- efficient pulp drying process is implemented in a paper mill using a combination of overpressure dryer and mechanical vapour recompressor.

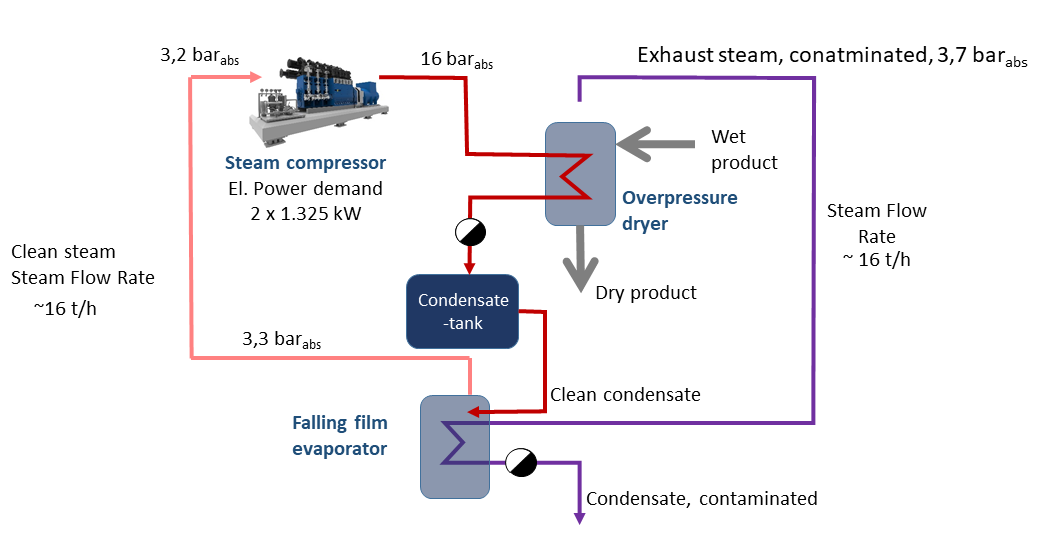

The overpressure dryer used, with rotary valves on the product inlet and outlet side, is heated from the outside with 16 bar(abs) steam (steam temperature approx. 200°C). In the fluidized bed, in which the drying takes place, 3.7 bar(abs) prevail. At this pressure level, the moisture of the wet paper pulp now also escapes.. A large part of the heat input for drying is found as heat of evaporation in the vapor produced.

The idea is now to compress the 3.7 bar(abs) exhaust vapor to 16 bar(abs) by mechanical vapor compression in order to make it usable again as a heating medium for the overpressure dryer. The drying plant is thus virtually self-heating. A steam piston compressor is used. With this type of compressor comparatively high compression pressure ratios and high outlet pressures are possible. In addition, it has very good internal efficiencies, so that the vapor compression can be carried out in an extremely energy-efficient manner.

Since the 3.7 bar(abs) vapor is contaminated with particles and other aggressive components, it is not fed directly to the piston compressor. Instead, it is used as a heating medium for a falling film evaporator, in which pure condensate evaporates into clean steam. At approx. 3.3 bar(abs), the resulting clean steam has a pressure level only slightly lower than the contaminated steam . This clean steam can now be compressed again to 16 bar(abs) with the piston compressor.

Two 6-cylinder steam compressors are in operation at the paper mill, which together compress 16 t/h of steam from 3.3 to 16 bar(abs). The compressed steam volume corresponds to a heat output of approx. 11,200 kW(th). Electric motors with a power input of 2 x 1,325 kW(el) are used to drive the compressors. The electricity deman is thus only approx. 23 percent compared to the steam output that can be used again. In other words, with each kWh of electricity used, approx. 4.2 kWh of steam heat is made usable again. This results in considerable CO2 savings. Compared to a natural gas-fired steam boiler, in which the 16 t/h of heating steam would otherwise have been generated, approx. 7,400 t/a of CO2 can be saved at an annual steam volume of 120,000 t/a and based on the emissions of the German electricity mix (as of 2019)1.

Profitability analysis

In the example shown below, we have calculated that for a plant operator with typical energy prices in Germany, an annual saving of approximately 1,028,000 euros would result. The system would pay for itself after 4.4 years (without subsidies3).

| Characteristics for steam compression from 3.3 to 16 bara, 16 t/h steam throughput | ||

| electrical power consumption at 16 t/h steam throughput | 2,65 | MW |

| thermal capacity recycled steam quantity of 16 t/h | 11,20 | MW |

| assumed hours of full use | 7.500 | h/Jahr |

| Investment costs | ||

| Steam compressor with accessories: | 2.500.000 | Euro |

| Periphery (falling film evaporator, buildings, pipeline construction etc.): | 2.000.000 | Euro |

| Operating costs of steam compressors | 1.710.000 | Euro/year |

| Maintenance costs: | 120.000 | Euro/year |

| Energy costs (electricity): | 1.590.000 | Euro/year |

| Savings in operating costs (gas boiler) | 2.737.800 | Euro/year |

| Energy cost savings (natural gas):* | 2.520.000 | Euro/year |

| Savings CO2 tax2: | 217.800 | Euro/year |

| Total annual savings | 1.027.800 | Euro/year |

| Total annual CO2 savings | 7.400 | tons/year |

| Payback period | 4,4 | years |

| Basis: Costs: Natural gas: 30 Euro/MWh; electricity: 80 Euro/MWh; CO2: 30 Euro/tCO2 emissions: Natural gas: 0.2 t/MWh; electricity: 0.48 t/MWh *for alternative HP steam generation with natural gas-fired steam boiler |

Our experts also have suitable solution proposals for your application. You can contact

us here.

1 CO2 saving

(11,200 kW x 0.202 kg CO2/kWh x 7,500 h/a) - (0.48 kg CO2/kWh x 2,650 kW x 7500h/a) = ~ 7,400 t CO2/a

2 CO2 tax

the calculation was made taking into account a future CO2 tax. Here, taxes of 25 euros per tonne are planned in Germany from 2021, rising to 55 euros per tonne by 2025. The assumed 30 euros per tonne of CO2 are therefore rather low.

3 BMWi support programs for energy efficiency

The BMWi's "Deutschland machts effizient" (Germany makes it efficient) funding programme provides, among other things, investment grants of up to 30 percent (for small and medium-sized enterprises (SMEs) even up to 40 percent) for projects to use waste heat. The upper limit is currently 500 Euro max. subsidy per saved annual ton of CO2 (or 700 Euro/t for SMEs). This would make it possible to reduce the payback period even further.