Spilling get’s more from what’s left over

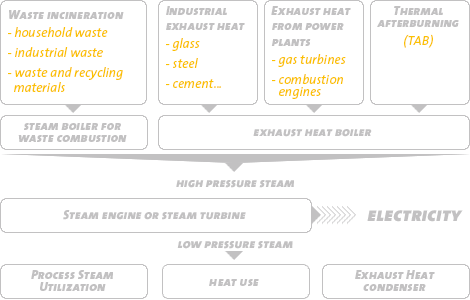

A typical application field for Spilling steam engines and steam turbines is the recycling of exhaust heat, waste and lean gases to generate mechanical and electrical energy.

Steam turbines are preferably installed when no heat is required after the process and the steam mass flow is large or constant enough. Single-stage or multi-stage steam turbines are employed as condensing units depending on the live steam parameters. The exhaust heat is discharged into a downstream (vacuum) condenser and so, as much electricity as possible is generated.

Steam engines are especially in demand when the heat from exhaust steam can be used during back pressure operation and fluctuating steam amounts exist, or when using a steam turbine would not be economical due to the steam mass flows available.