Recovery of steam from an exothermal process to supply high pressure steam to heat exchanger in the petrochemical industry.

Steam at 9 bar is produced by an exhaust heat steam generator in an exothermal process downstream from the heat exchanger. However, steam of this quality cannot be used in the plant, but a pressure of 21 bar is required for two heat exchanger units. The high pressure steam can either be provided as live steam over a reducing valve from a 32 bar steam mains or the 9 bar excess steam can be compressed using a steam compressor to the required pressure level.

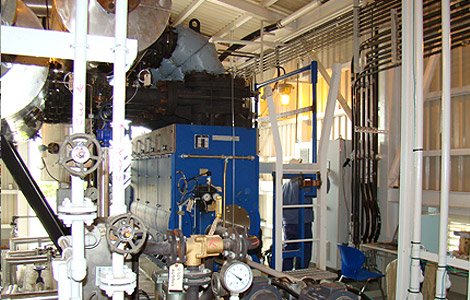

The choice was the most economic solution from the customer point of view – a Spilling compressor with a medium voltage variable speed drive that can be operated more cost effectively using electricity rather than fossil fuels.